Foam Crown Molding Wire Raceway

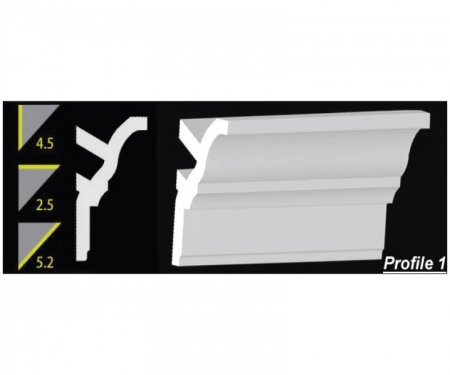

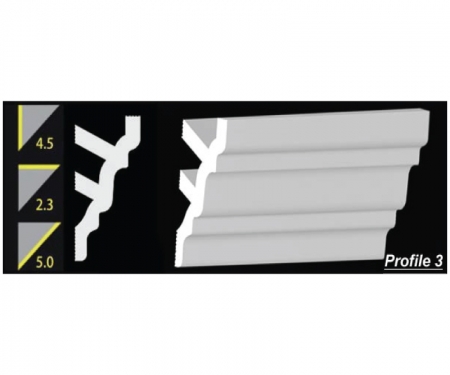

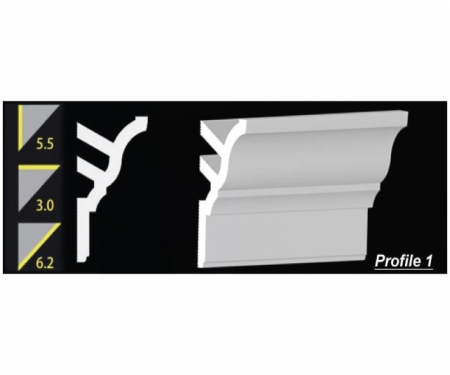

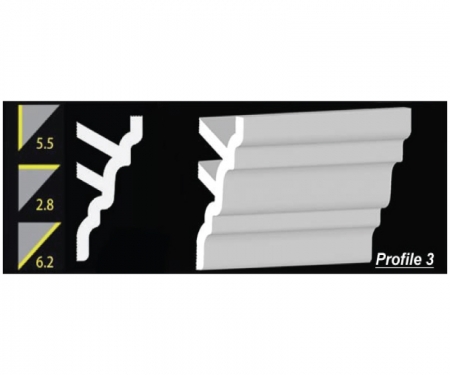

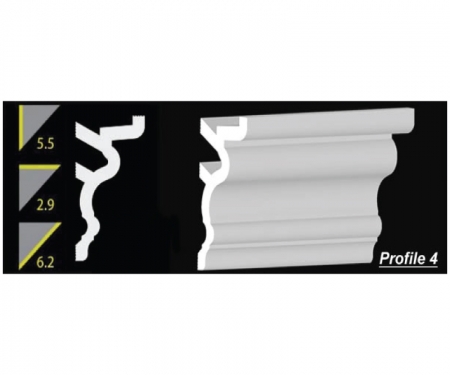

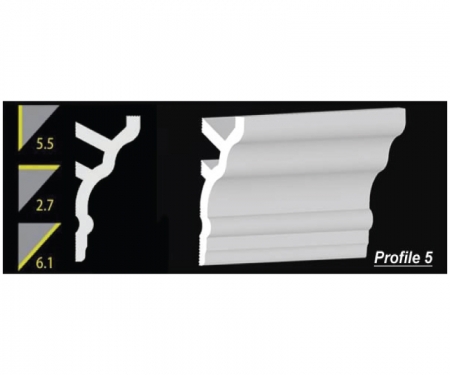

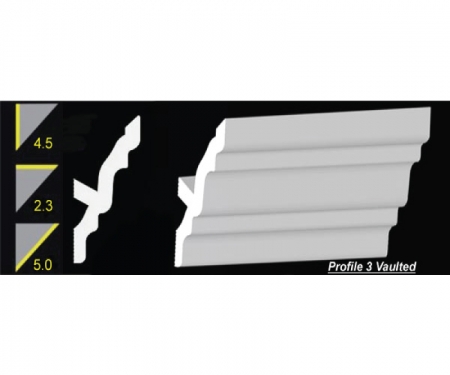

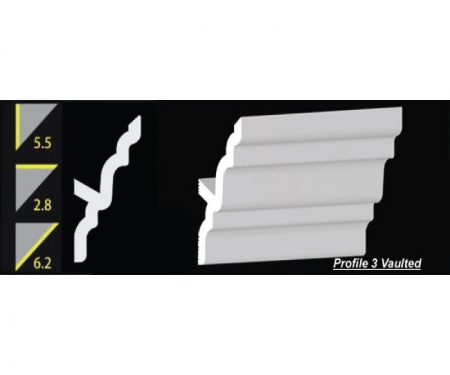

Available In 3 Different Heights & 6 Different Profile Styles

0.0 / 5

Foam Crown Molding Cable Raceway Features

- FREE SHIPPING

- Ideal For Concealing Cables & Wires, On Long Runs

- Installs onto Any Surface

- Easy To Install, No Nails, Screws, Clips or Fasteners Required

- Paintable - Molding Surface Only Requires One Coat of Water Based Latex Paint

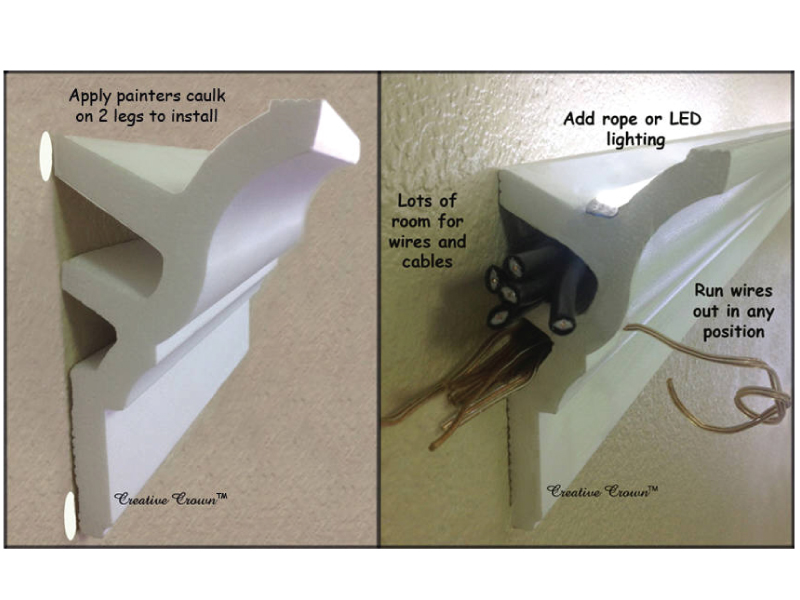

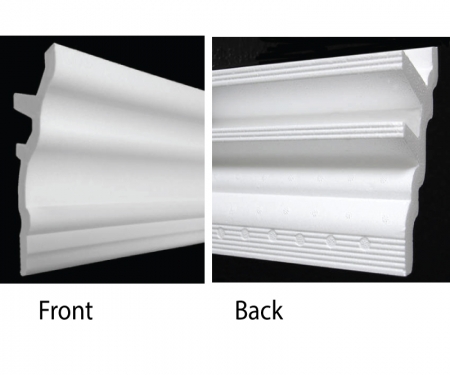

Foam crown molding cable raceways are smooth, high density, flat back foam crown moldings and we are the first and only crown molding with this design. Foam crown molding wire raceways cost less than wood crown moldings and polyurethane, urethane moldings. It is the most inexpensive decorative crown molding that you will find today. Customers achieve a professional look without the cost, mess, and headaches of wood or plastic crown molding installations. The surface of the molding cable raceway features Skin Tec technology (a perfectly smooth surface) that makes painting a breeze. No primer is needed. Installs with painters caulk and cuts in most positions in most miter saws!

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

Wall and ceiling installation

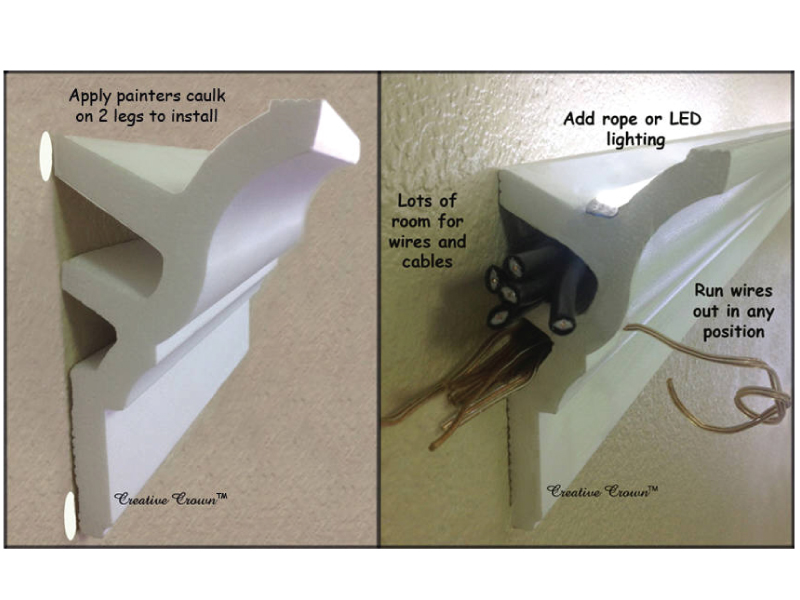

When installing on a regular flat ceiling, just apply a bead of painters caulk about the size of a pencil on

the top where the molding fits to the ceiling and a bead on the back bottom edge where it fits to the wall.

Next, just press the molding firmly into the wall and ceiling.

Then wipe off any extra caulk and you have installed and caulked your seams in one step. No nailing!

ALL Foam Crown Molding Is Made To Order & Is Non-Cancellable / Non-Refundable

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Looking for a quotation ? We would be happy to help by providing a quick response, inventory status, and Volume Level pricing, when available. Please fill out the form below and a representative will be in touch with you within hours to one business day to answer any questions and quote your request.

Product Details

Foam crown molding cable raceways are smooth, high density, flat back foam crown moldings and we are the first and only crown molding with this design. Foam crown molding wire raceways cost less than wood crown moldings and polyurethane, urethane moldings. It is the most inexpensive decorative crown molding that you will find today. Customers achieve a professional look without the cost, mess, and headaches of wood or plastic crown molding installations. The surface of the molding cable raceway features Skin Tec technology (a perfectly smooth surface) that makes painting a breeze. No primer is needed. Installs with painters caulk and cuts in most positions in most miter saws!

Product Specifications

Are we missing the specification you need? Please go to our Contact Us page and submit your question to us, or call 1-877-284-7760

Wall and ceiling installation

When installing on a regular flat ceiling, just apply a bead of painters caulk about the size of a pencil on

the top where the molding fits to the ceiling and a bead on the back bottom edge where it fits to the wall.

Next, just press the molding firmly into the wall and ceiling.

Then wipe off any extra caulk and you have installed and caulked your seams in one step. No nailing!

Product Manuals

Frequently Asked Questions

Have a question that is not answered here? Please go to our Contact Us page and submit your question to us.

Videos

ALL Foam Crown Molding Is Made To Order & Is Non-Cancellable / Non-Refundable

.jpg)